What is DEF CAP and Its Importance?

In modern diesel engines, DEF (Diesel Exhaust Fluid) plays a crucial role in reducing nitrogen oxides (NOx) emissions, helping the engine meet strict emission standards. DEF is made up of 32.5% urea and 67.5% deionized water. It is injected into the exhaust system through a Selective Catalytic Reduction (SCR) system, where it is converted into nitrogen and water vapor. While DEF is essential for environmental protection, its storage and handling are just as important. The DEF CAP, which seals the DEF storage tank, ensures the fluid remains safe and clean.

In this blog post, we will dive into the role of the DEF CAP, its importance, and how to properly use and maintain it.

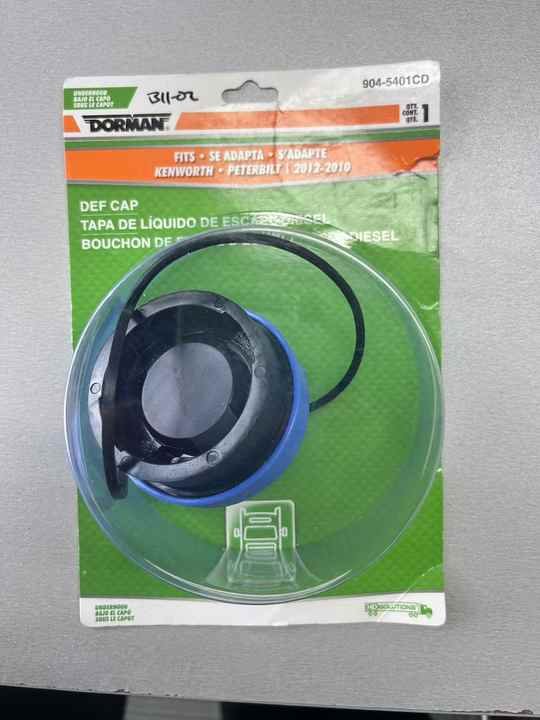

What is a DEF CAP?

A DEF CAP is the component used to seal the DEF storage tank opening. It plays a crucial role in ensuring that the DEF fluid remains uncontaminated. Since DEF purity is essential for the SCR system to function properly, the DEF CAP is designed to not only provide a secure seal but also to prevent contaminants such as dust, dirt, and moisture from entering the tank, which could otherwise compromise the quality of the DEF.

In modern trucks and heavy-duty equipment, the DEF storage tank is often located near the fuel tank, and the DEF CAP is placed over the filling port. It is a well-designed component that ensures the fluid is securely contained and prevents leaks.

The Role and Importance of the DEF CAP

- Prevents Contamination: DEF fluid has very stringent purity requirements. If DEF becomes contaminated—particularly with water, dirt, or other impurities—it can cause the SCR system to malfunction, affecting engine emissions performance. The DEF CAP provides a protective seal, preventing such contaminants from entering the tank.

- Maintains Fluid Quality: The stability and chemical composition of DEF must remain unchanged. The DEF CAP ensures that the fluid is protected from evaporation or exposure to temperature and humidity extremes, preserving its chemical integrity.

- Prevents Leaks: During long hauls or in rough conditions, vehicles may experience vibrations or bumps. If the DEF CAP is not properly sealed, DEF fluid may leak, leading to unnecessary waste and potential environmental hazards. A high-quality DEF CAP ensures that fluid stays contained and no leaks occur.

- Convenience for Users: A well-designed DEF CAP should be easy to open and close, providing users with a hassle-free experience when refilling DEF fluid. It should ensure that no fluid leaks out during refilling while also securely closing when not in use, preventing fluid loss.

How to Properly Use and Maintain the DEF CAP?

- Regularly Check the Seal of the DEF CAP: The primary function of the DEF CAP is to provide a secure seal. Therefore, it is important to regularly inspect the cap for any signs of damage, such as cracks or wear. If the cap is damaged, it should be replaced immediately.

- Clean and Maintain: The DEF CAP should be kept clean to prevent external dirt from contaminating the fluid. Wipe the cap with a clean cloth, but avoid using harsh chemicals that could damage the sealing material.

- Careful Handling During Refilling: When refilling the DEF tank, ensure that the DEF CAP is properly opened. After refilling, securely tighten the cap to avoid leaks or contamination. Loose or improperly closed caps can lead to DEF leakage or moisture exposure.

- Avoid Contamination: When handling the DEF fluid, ensure that the DEF CAP remains sealed at all times. When opening the cap, try to avoid letting it come into contact with the ground or any unclean surfaces to prevent contamination of the fluid.

- Replace Worn-out DEF CAP: Over time, the DEF CAP’s seal and material may degrade. If the cap shows signs of wear or improper sealing, it should be replaced promptly to maintain the integrity of the DEF fluid and the engine’s emission system.

How to Choose the Right DEF CAP?

Choosing the right DEF CAP is essential for ensuring the proper storage and handling of DEF fluid. Here are a few tips for selecting the right DEF CAP:

- Match the Vehicle or Equipment: Ensure that the DEF CAP is compatible with your vehicle or equipment model. Different vehicles may require different sizes or designs of DEF caps.

- High-Quality Materials: Choose a cap made from durable, UV-resistant, and corrosion-resistant materials to ensure a longer lifespan.

- User-Friendly Design: A high-quality DEF CAP should be easy to operate, allowing for convenient refilling and secure sealing.

Conclusion

Although the DEF CAP is a small component, it plays an essential role in the overall performance of the diesel engine emissions system. It not only prevents contamination and leakage of the DEF fluid but also ensures the proper operation of the SCR system, which is crucial for reducing harmful emissions and optimizing engine performance.

Proper use and maintenance of the DEF CAP are key to keeping the DEF fluid quality intact and ensuring the emission system functions efficiently. If your DEF CAP shows signs of damage or wear, it’s important to replace it promptly to avoid engine performance issues and maintain your vehicle’s compliance with emission standards.

If you intend to purchase such products, please visit our website for consultation.

Our Websitie:aifueltankcap.com